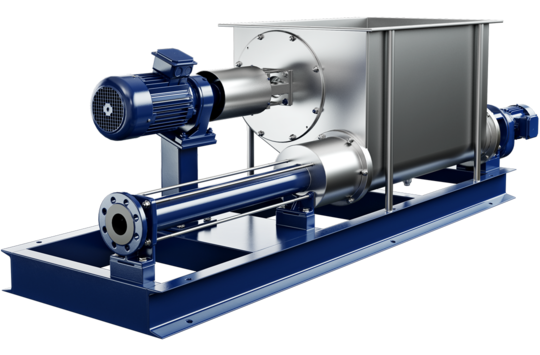

No stoppages, no bridging: to ensure the feed medium can be optimally pumped at all times, there is a bridge breaker above the screw conveyor in the rectangular hopper of the BTEI hopper pump from SEEPEX. The separately driven rotating paddle keeps the medium in constant motion, thus avoiding the formation of bridges. A further benefit of the range: in order to save space in the processing system, a closed buffer tank can optionally be connected. A separate reservoir is therefore not required.

SPACE-SAVING

The optional integrated buffer tank replaces the separate reservoir tank saving space in the processing system

NO BRIDGING

Thanks to the bridge breaker, which consists of a rotating paddle shaft, the medium is in constant motion

OPTIMUM PRODUCT CONVEYANCE

Feed flow to the screw conveyor is guaranteed, even for highly viscous products, thanks to bridge breaker

FLEXIBLE CONTROL

Flexible adjustment of speed thanks to separate drive system for bridge breaker – irrespective of pump speed

PROCESS CONTROL

Optional: Installation of various sensors for processing monitoring, e.g. for checking filling level

With gauge connection. Flange connections alternatively to DIN or ANSI.

© 2023 SEEPEX GmbH All rights reserved.

PROGRESSIVE CAVITY PUMP EXPERTS.

INNOVATIVE PRODUCTS. CUSTOMIZED SOLUTIONS.