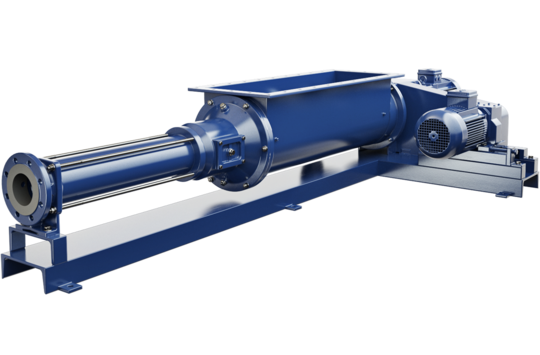

Always the right speed: Because the ribbon screw of the BTH hopper pump from SEEPEX has its own separate second drive system, it can be operated at a different speed from the rotating unit. Thanks to the large diameter and elongated pitch of the edge-to-edge ribbon screw, even media that tend to bridge can be conveyed without any problems.

OPTIMAL SPEED

The speed is always optimally adjusted to the medium thanks to the separately driven ribbon screw in the hopper, which is operated at a different speed

NO BRIDGING

The centrally oriented, edge-to-edge ribbon screw has a large diameter and elongated pitch, ensuring no bridging takes place with highly viscous or semi-solid media

OPTIMUM PRODUCT CONVEYANCE

Conveyance of the optimal flow rate to the downstream rotating unit by compressing the medium in the compression zone

EASY MAINTENANCE

Quick and simple maintenance thanks to the easy dismantling of the compression casing

CONSISTENT VISCOSITY

Thanks to the low speed of the screw conveyor and rotating unit when transporting media that is sensitive to shearing

VARIABLE

Available in block design with directly flanged-on drive system, or as a variant with free bare shaft and plug connection

With gauge connection. Flange connections alternatively to DIN or ANSI.

© 2023 SEEPEX GmbH All rights reserved.

PROGRESSIVE CAVITY PUMP EXPERTS.

INNOVATIVE PRODUCTS. CUSTOMIZED SOLUTIONS.